Reverse osmosis takes place in reverse osmosis plant which is a manufacturing plant. This process requires 6 kilo watt hours electricity to desalinate a cubic meter of water. This whole process dispose a salty briny water. A biggest challenge for these reverse osmosis plant is to come up with to minimise energy consumption, employ sustainable energy sources, enhances the desalination process and develop in the field of waste management to manage with waste.

RO is a manufacturing plant where basis process of reverse osmosis take place. RO plant requires at least six KW per hour of electricity in order to desalinate at least one cubic meter of water. Reverse osmosis is a process that occurs when a fluid is transported through a barrier by another , more concentrated fluid on other side.

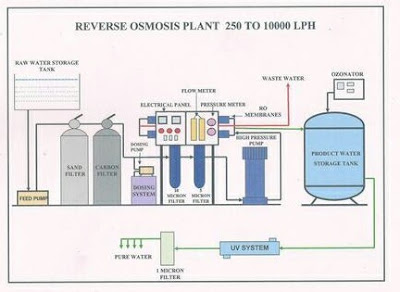

The working of the Reverse osmosis plant is divided into five stages -

• Stage 1

Removes sediment, dirt, sand and all the other physical particles.

• Stage 2

A granular and carbon filter helps in the reduction of organics, chlorine, odor, turbidity and smell from the entire water.

• Stage 3

In this stage the carbon filter is blocked and this further reduces odors, chlorine and various other harmful chemicals.

• Stage 4

Here the reverse osmosis membrane removes bacteria, salt, heavy metals and all the other bad mineral substances and also the various other dissolved matter as well as chemical drugs from the water.

• Stage 5

This is the rear anti- bacterium that is activated because of the carbon filter and a one that can improve the taste of any type of water.

These Reverse Osmosis systems are used in homes , offices, hospitals, nursery homes, clinics, gyms, beauty salons, restaurants, schools and shops. It is important to learn more about RO plant types because it is only going to help us in the long run. Reverse Osmosis systems are the easiest, effective and economical means of providing safe , healthy water for you and your Family.

Comments

Post a Comment